- 2006/7, GIDC, Vithal Udyognagar, Anand

- T. +91 2692 233677

We introduce ourselves as one of the leading manufacturer of Automation Panel for ISPM-15 approved FHAT Plant with government inspection and its working successfully many customers of India. We also modify your old panel with our hi- tech and latest Automation Panel with latest Data logging Software.

Through our Automaton Panel you can control and record Temperature & Humidity of your plant. We can also provide you web based data monitor and record from you access your data on mobile and laptop.

We also manufacture PLC based Automation Panel for Wood Seasoning Plant with Auto-Manual system, which control and record Temperature Humidity and moisture of your Plant with Online Digital Moisture Indication. It is also Programmable for any kind of Wood.

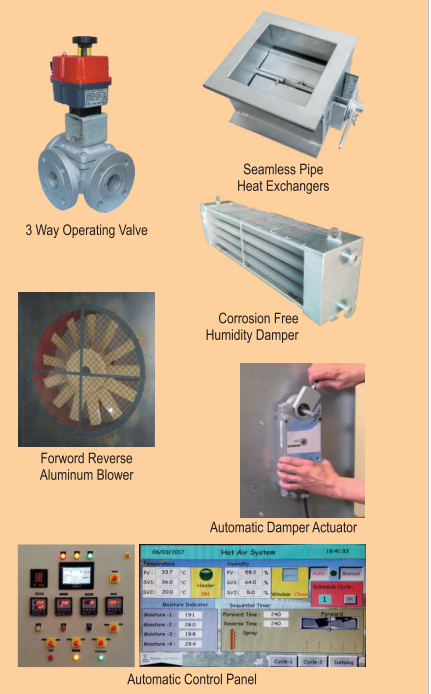

A) Touch pane control with programmable for any kind of wood. 15 no. programmes can be stored inside touch panel. All process parameters like temperature, humidity, moisture can be record as per date and time to analyse your treatment. One Temperature controller which operate control valve/heater/ burner to control the heating of your chamber. One safety Temperature controller, for annunciation in case of over/under temperature One Humidity Controller which operate humidity window and spray to control the humidity inside the chamber. One 4- channel Moisture Indicator which indicate moisture inside the wood of four different location. Forward time, reverse time and hold time can be settable from touch panel. All control parameter like temperature, humidity, fan etc. can be control auto as well as manual mode.

B) Heat Exchangers: Heat Exchangers are made up of seamless pipe finning with high tensile sheet which having high efficiency of heat transfer,

C) Blower; The air ventilation is provided by reversible fans with high performance level installed in chamber. The fans can perform with the same efficiency and capacity in both direction and at any revolution rate. Each fan has 13 aluminum blades with perfectly symmetrical shape. The aluminum fan 900 mm mountain on shaft of the specially designed with high speed taper rolling bearings,

D) Damper Actuators: The damper actuator is standard with 9nm torque with corrosion free dampers.

E) The stainless steel solenoid valve for heating and is resistant to corrosion and long service life.

F) Three way valve in thermic fluid heating system which saving energy through pass system.

Winsol Phytothermal System is a leading global brand of manufacturing and exporting wide range of Wood Seasoning equipments and plants since 1985.

Copyright © 2023. All rights reserved. Design & Development by Infoiconic

WhatsApp us