- 2006/7, GIDC, Vithal Udyognagar, Anand

- T. +91 2692 233677

When a tree is newly felled, it contains about 55% or more of its own weight as water. This water is in the form of sap and moisture. The water is to be removed before the timber can be used for any engineering purpose. In other words, The process of removing this moisture is referred to as seasoning and constitutes one of the most Important steps in converting raw wood into finished products.

This process of drying of timber is known as the seasoning of timber.

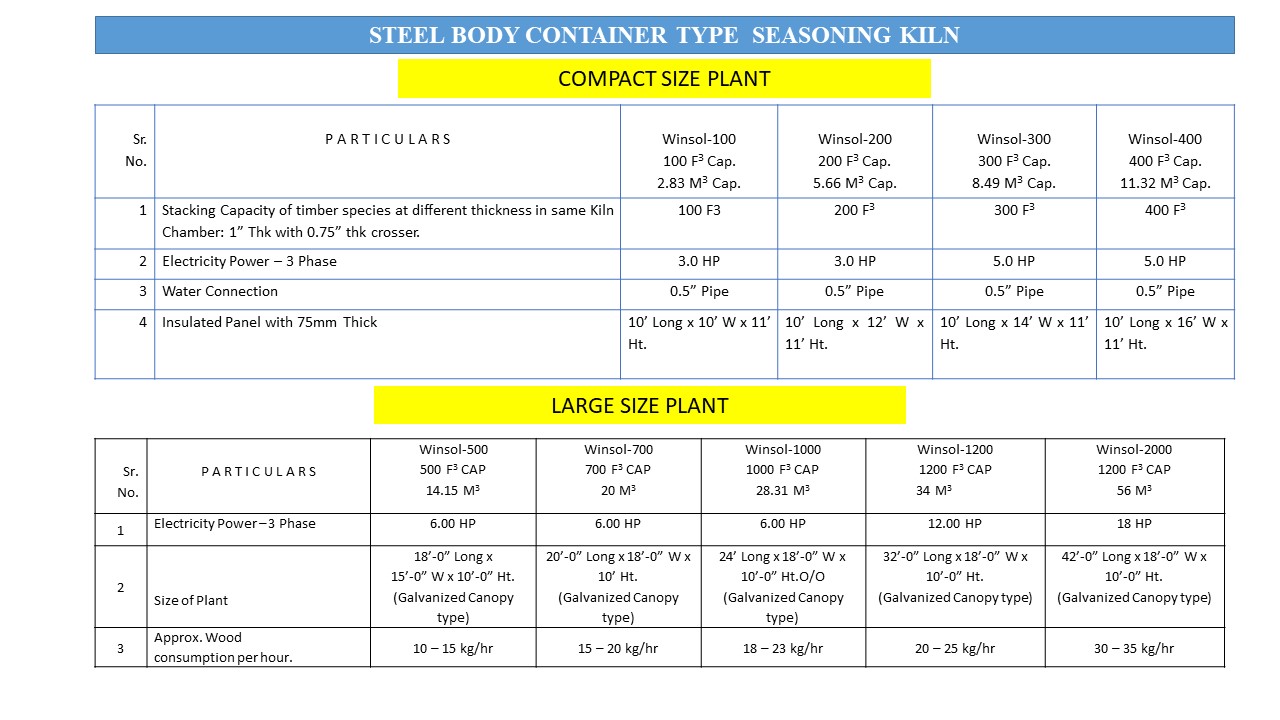

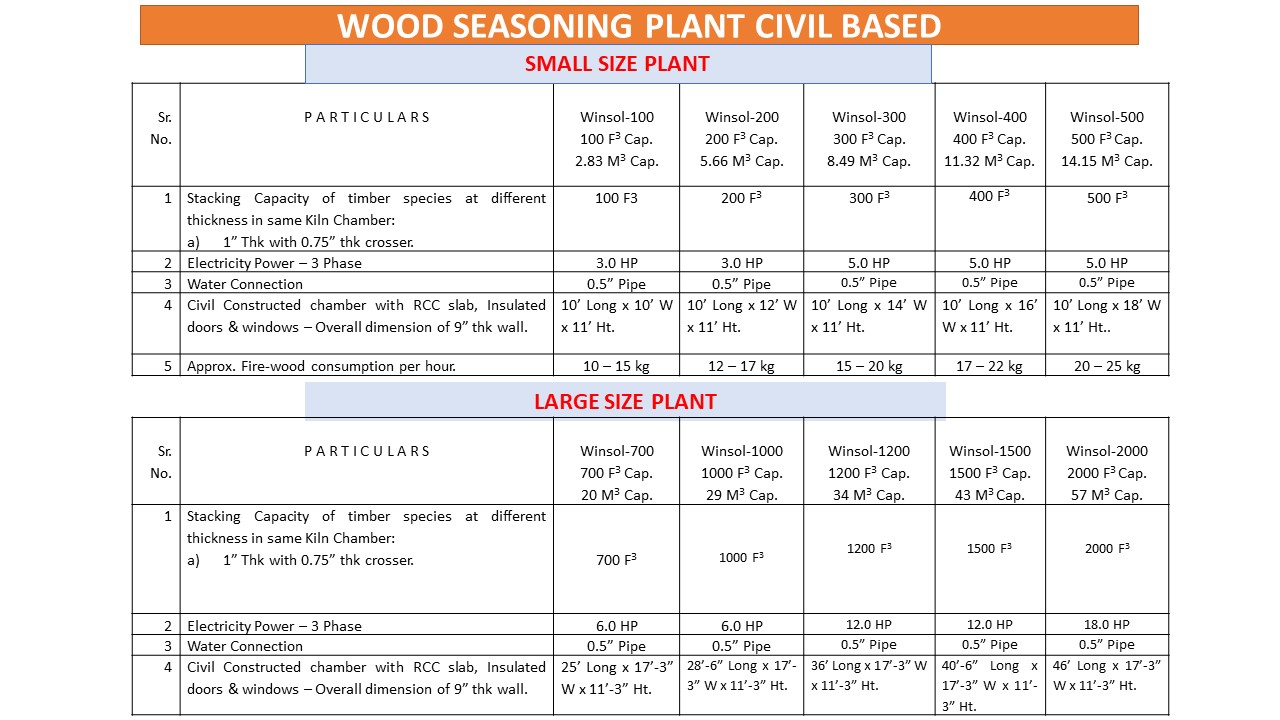

Timber seasoning by most effective and economic process by:

Wood waste fired furnace seasoning kiln OR Indirect heated internal heating system & fan furnace kiln.

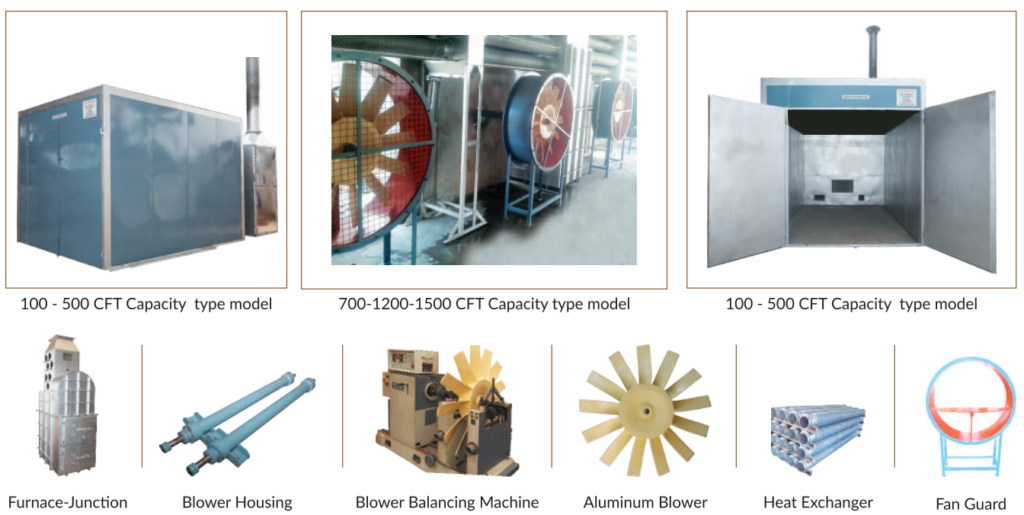

Winsol Phytothermal System is a leading global brand of manufacturing and exporting wide range of Wood Seasoning equipments and plants since 1985.

Copyright © 2023. All rights reserved. Design & Development by Infoiconic

WhatsApp us